The overall goal of inventory management is to transform the existing bimodal distribution, where excessive inventory and material shortages coexist, into a unimodal distribution where all materials are in the optimization region.

To achieve this goal, the following steps can be taken:

Step 1: Establish a raw material inventory buffer to reduce material shortages in the factory.

Step 2: Use lean tools to quickly streamline internal flow in the factory, reduce batch sizes, and ensure completeness.

Step 3: Use the OPEX-1588 business process tool to discuss finished goods inventory strategies and establish a PSI supply and demand balance plan.

Step 4: Improve the overall inventory plan and use low-inventory finished products to meet delivery requirements.

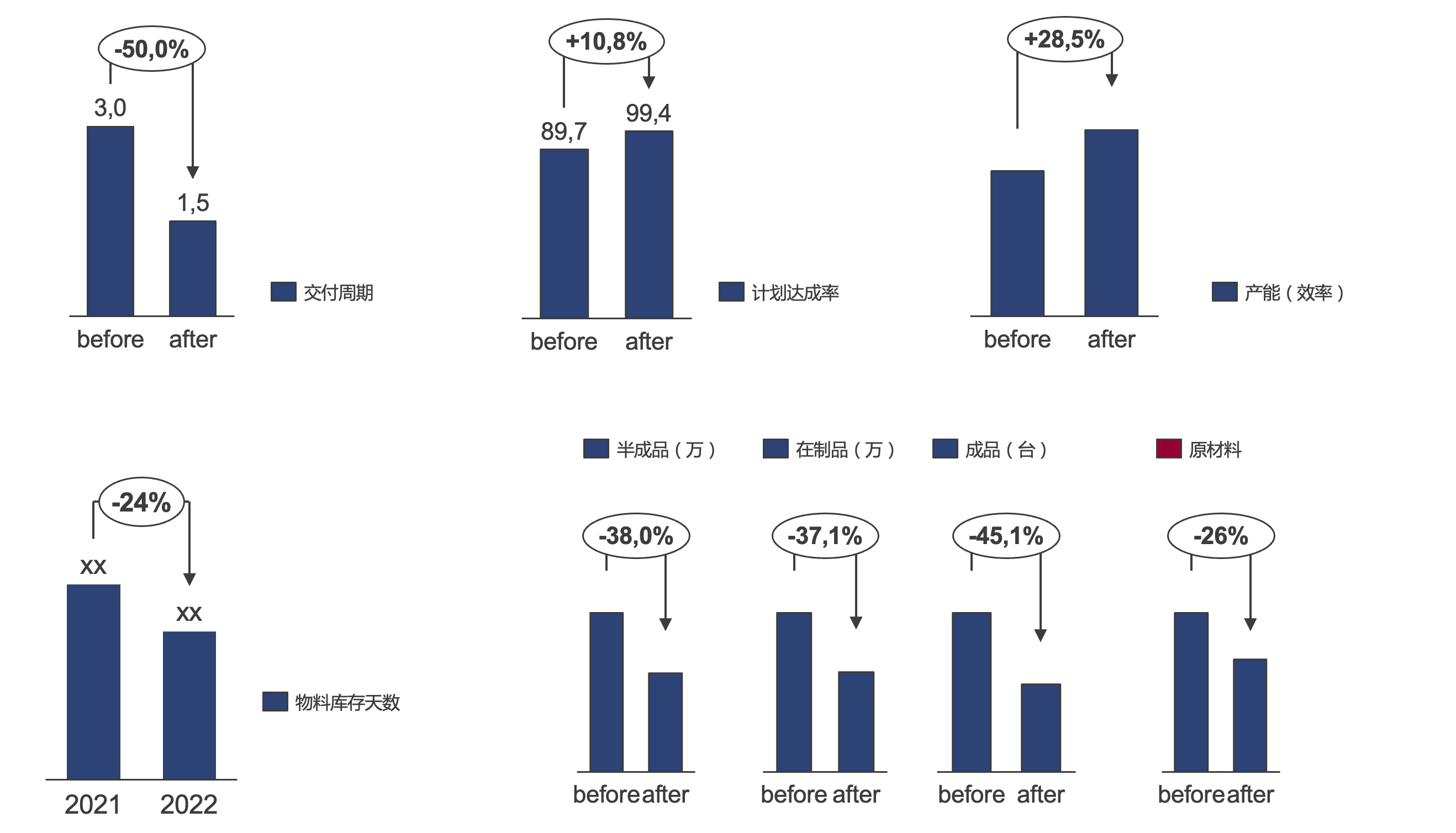

пјҲдёәе®ўжҲ·дҝқеҜҶпјҢд»…еұ•зӨәж”№е–„%ж•°жҚ®пјү

еә“еӯҳжҺ§еҲ¶иҪҜ件пјҢзү©ж–ҷйҪҗеҘ—жҺ§еҲ¶APPпјҡ

еҹ№и®ӯиҜҫзЁӢпјҢд»Һе®һжҲҳиҜҫзЁӢиҪ»жқҫејҖе§Ӣе…ЁеұҖеә“еӯҳз®ЎзҗҶж”№е–„пјҹ

гҖҠе…ЁеұҖеә“еӯҳз®ЎзҗҶ2еӨ©е®һжҲҳеҹ№и®ӯиҜҫзЁӢгҖӢ

еҜ»жұӮиҜҠж–ӯпјҹ

зӮ№еҮ»пјҡиҒ”зі»жҲ‘们иҺ·еҸ–зҷҪзҡ®д№Ұ/зҺ°еңәиҜҠж–ӯ

Contact Us

иҒ”зі»зғӯзәҝпјҡ400-101-9550

Email: bella@originflow.cn

ең°еқҖпјҡдёҠжө·еёӮйҮ‘еұұеҢәжј•жіҫй•ҮдәӯеҚ«е…¬и·Ҝ3688еҸ·5е№ў

Follow WeChat official account

Software Download

About Us

Our services

Excellence College

жІӘе…¬зҪ‘е®үеӨҮ жҢҡеҺҹдјҒдёҡз®ЎзҗҶе’ЁиҜўпјҲдёҠжө·пјүжңүйҷҗе…¬еҸёпјҢзүҲжқғжүҖжңүеӨҮжЎҲеҸ·пјҡжІӘICPеӨҮ17034718еҸ·