Our advisors have over 10 years of experience in industrial operations, management, and execution. We focus on identifying, designing, implementing, and continuously improving the value of your organization. We follow lean principles to eliminate waste, improve productivity, and enhance product quality.

We lead by example, focus on the situation, and work hand in hand with customers to implement changes, constantly reflecting to improve performance and develop talent.

Our typical clients are large-scale enterprises with multiple factories and branches. These clients' management and investors often have high standards and strict requirements, and are eager to double their performance and profit. We work closely with the company's management and investors to increase performance and profits, and maximize value for all stakeholders.

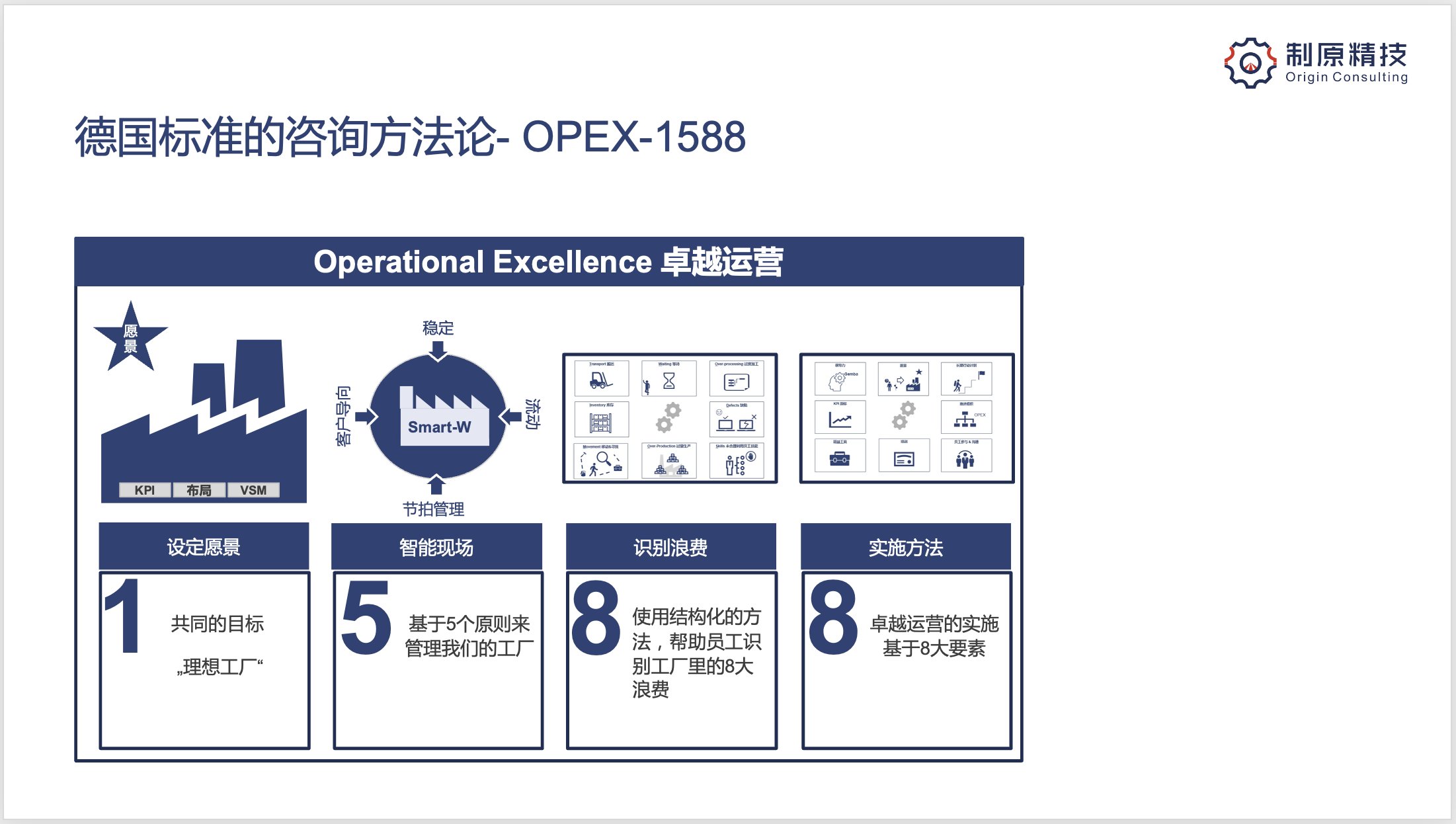

зӮ№еҮ»пјҡеҚ“и¶ҠиҝҗиҗҘOPEX-1588е·Ҙе…·з®ұ

зӮ№еҮ»пјҡеҚ“и¶ҠиҝҗиҗҘOPEX-1588и§Ҷйў‘

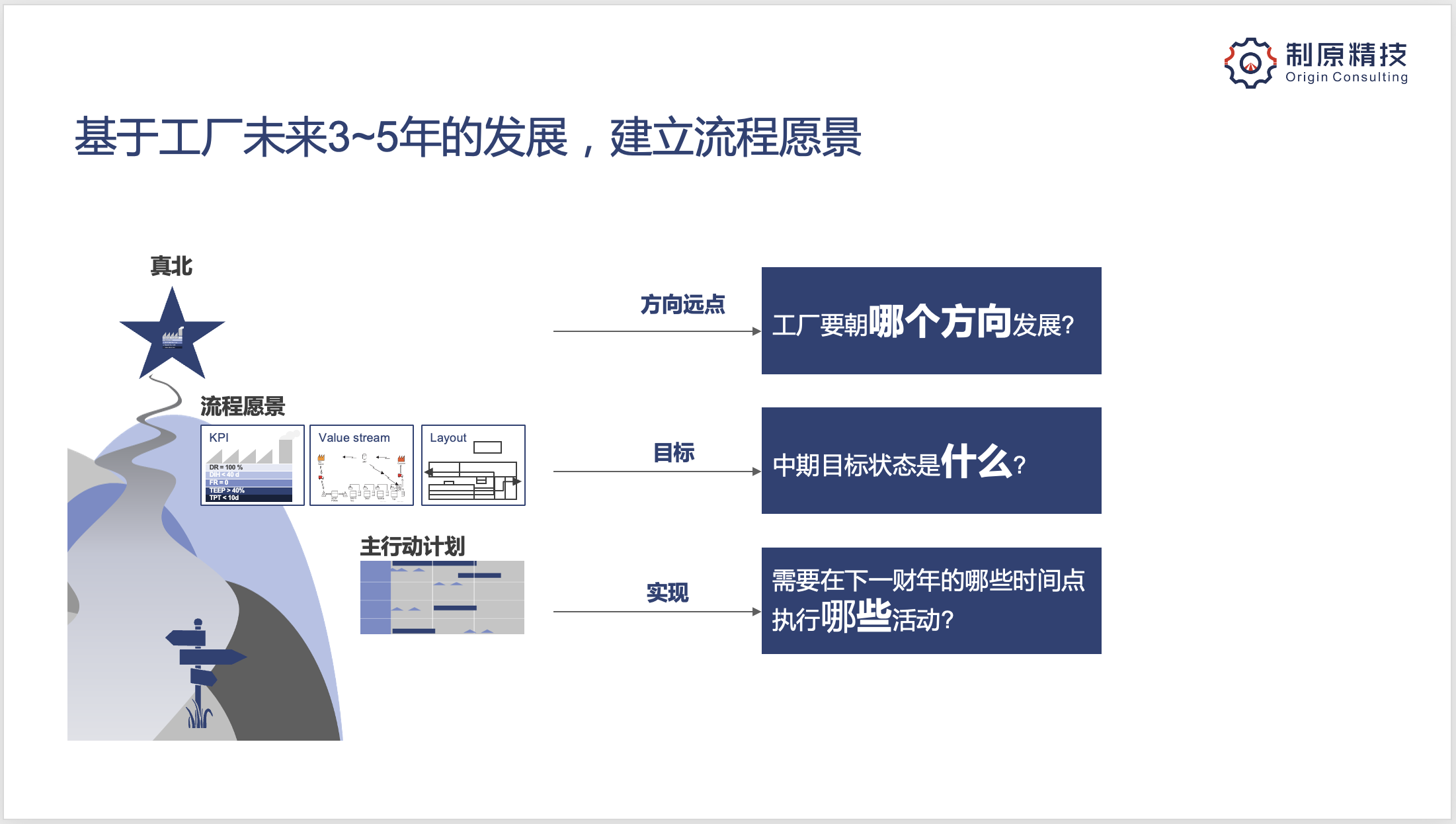

An ideal factory must have three essential components: a true north, a process vision, and a main action plan.

True north expresses the long-term (over 5 years) "reason for existence" of the factory, which is a defining characteristic of a factory. It outlines the core mission of the factory to meet customer needs.

The process vision consists of more specific structure and process goals, which are presented in the form of value stream design, layout diagrams, and KPIs for the next 3-5 years.

The goals of the process vision can be broken down into annual goals, which are visualized through the main action plan. Progress will be tracked weekly throughout the fiscal year, including all responsible parties and necessary resources.

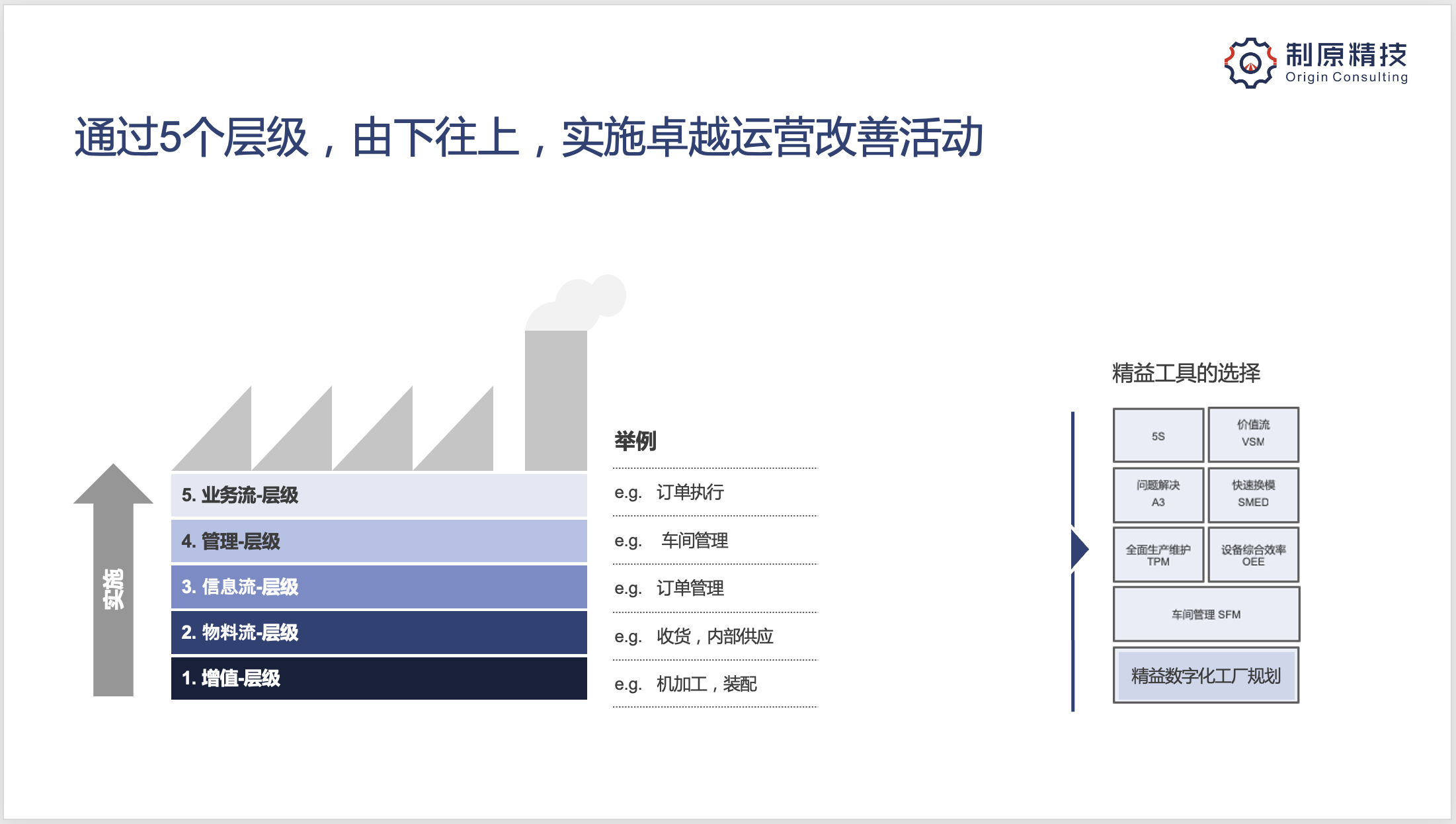

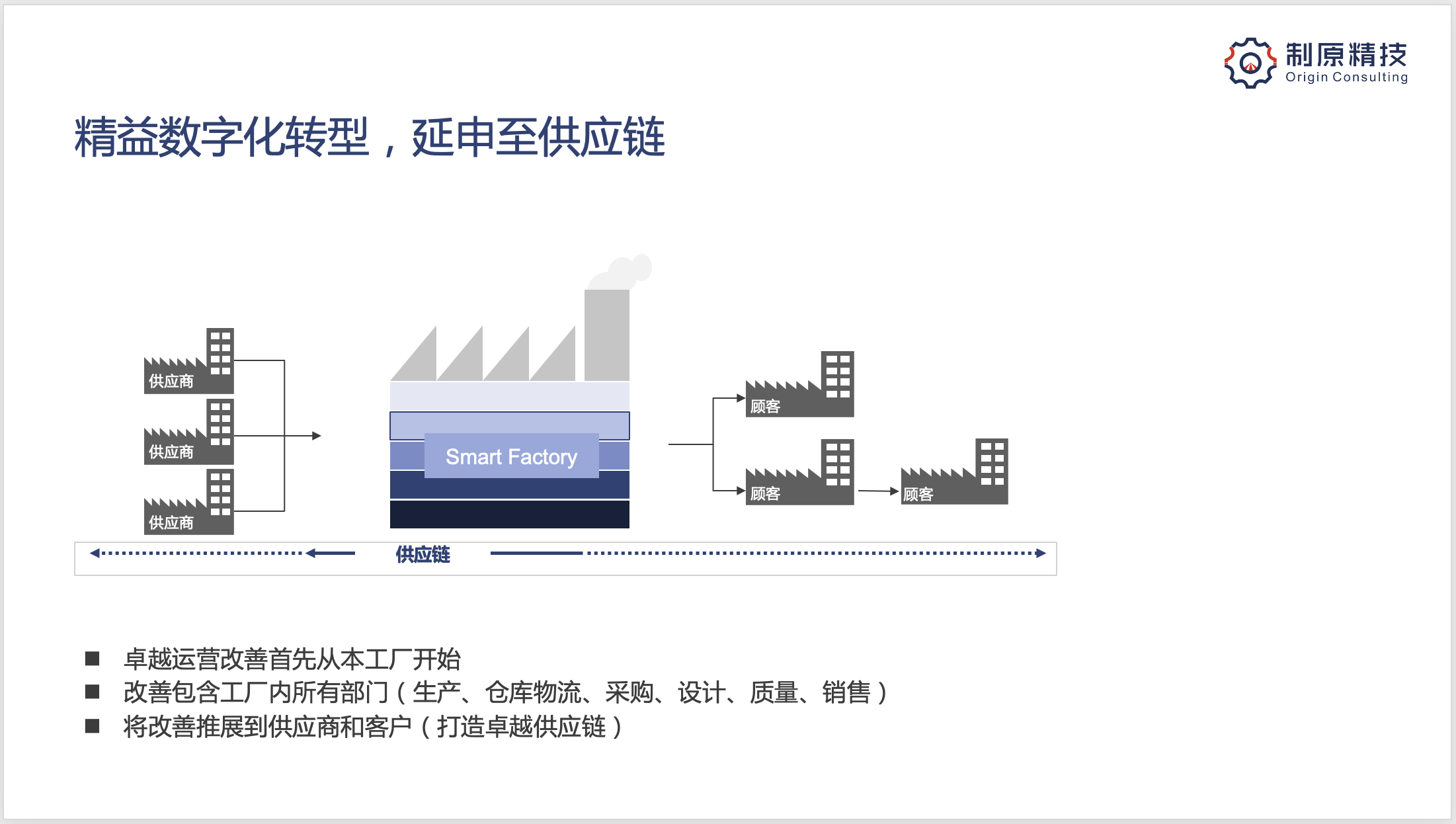

Kaizen actions should be implemented from the bottom to the top levels, which include the value-added layer, logistics layer, information layer, management layer, and business layer.

In the VUCA era, it is advisable to initially focus on improving the coordination status of the supply chain at the business and information flow levels.

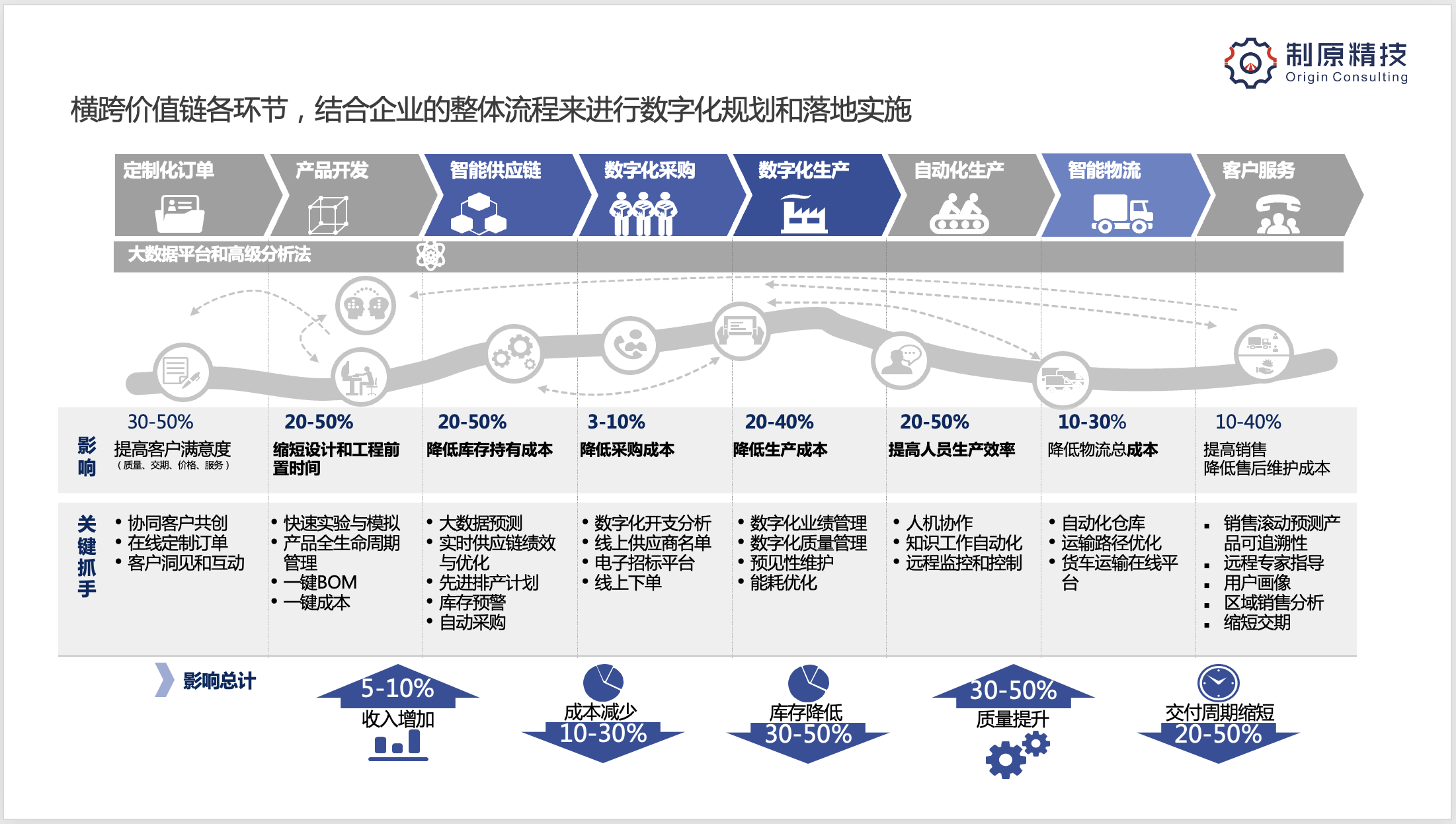

The factory process vision strategy involves evaluating the existing IT infrastructure to identify digitalization needs and plan the implementation roadmap.

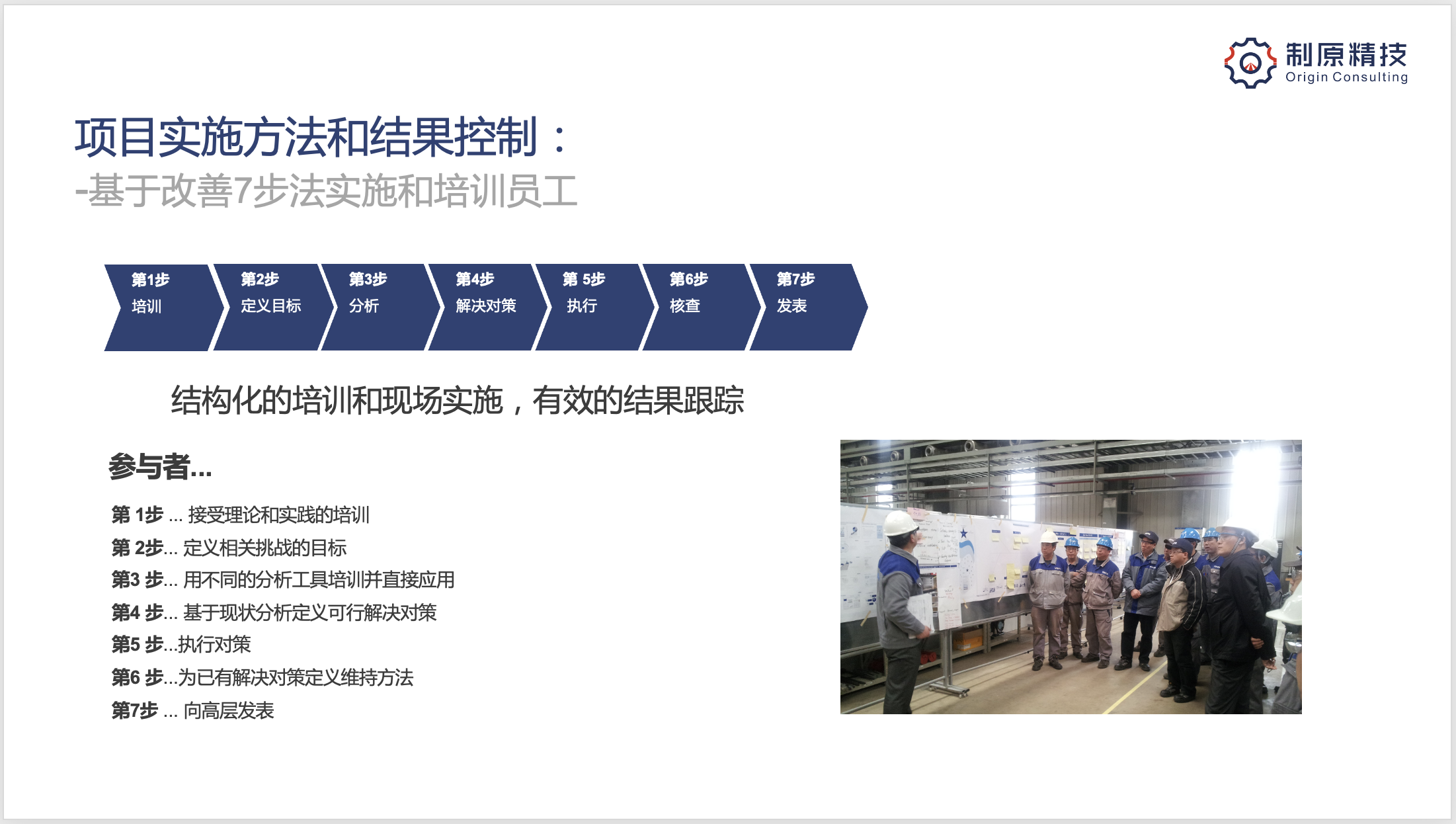

Our project implementation strictly follows the 7-step method of improvement activities. This requires a structured and visualized problem-solving process.

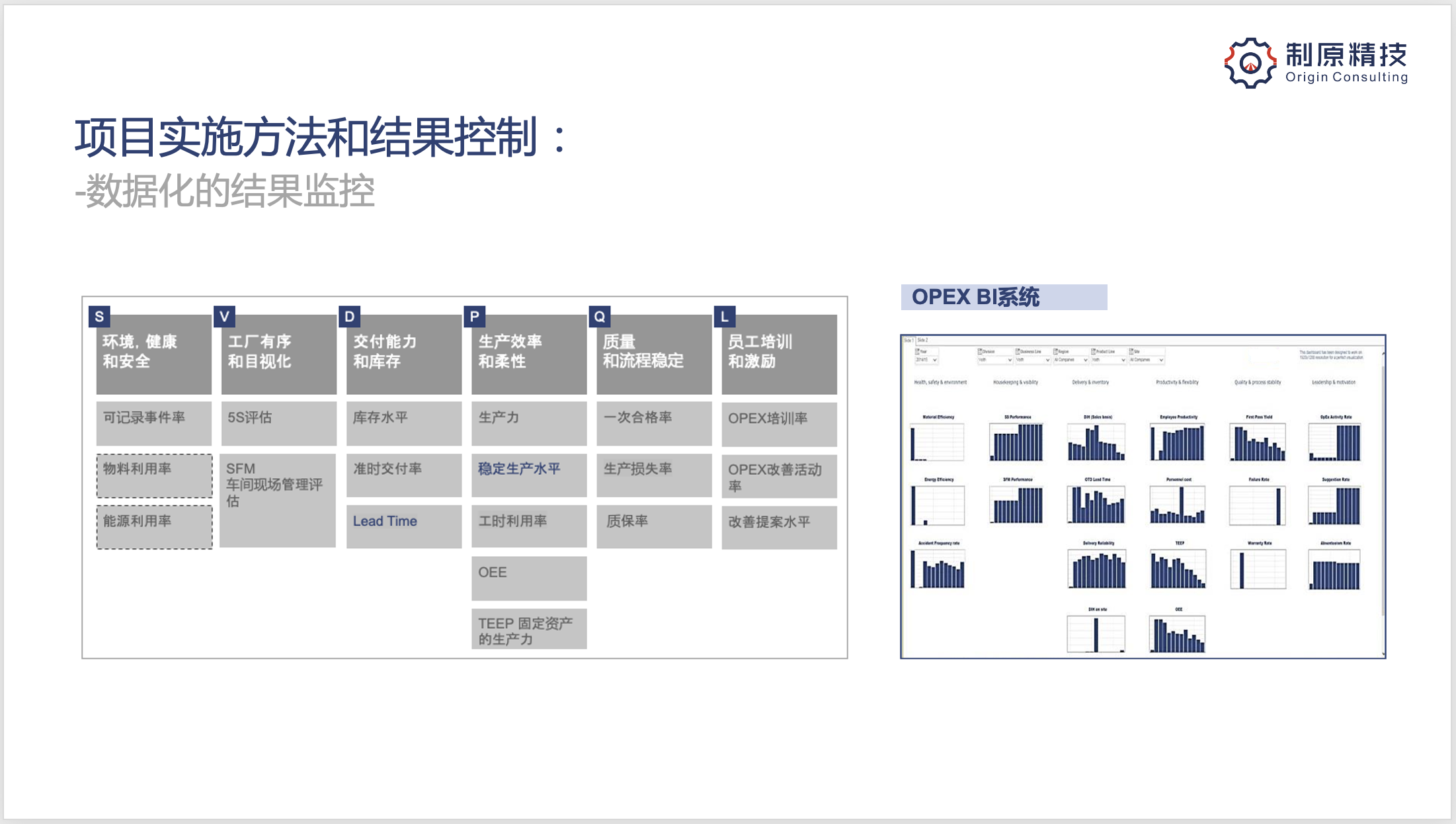

The OPEX KPI system sets the direction for achieving the company's highest goals. This structured indicator system enables the operations, supply chain, and improvement teams to focus on the most critical indicators of the company, and monitor and display improvement results.

жү«з ҒжҹҘзңӢпјҡеҲ¶еҺҹз®ЎзҗҶе’ЁиҜўе®Јдј йЎө

Contact Us

иҒ”зі»зғӯзәҝпјҡ400-101-9550

Email: bella@originflow.cn

ең°еқҖпјҡдёҠжө·еёӮйҮ‘еұұеҢәжј•жіҫй•ҮдәӯеҚ«е…¬и·Ҝ3688еҸ·5е№ў

Follow WeChat official account

Software Download

About Us

Our services

Excellence College

жІӘе…¬зҪ‘е®үеӨҮ жҢҡеҺҹдјҒдёҡз®ЎзҗҶе’ЁиҜўпјҲдёҠжө·пјүжңүйҷҗе…¬еҸёпјҢзүҲжқғжүҖжңүеӨҮжЎҲеҸ·пјҡжІӘICPеӨҮ17034718еҸ·